When bores in heavy equipment become worn or out of round, two repair methods are commonly used: bore welding and line boring. While they are often mentioned together, they are not the same process. Knowing the difference can save your business time and money. In this article, we compare bore welding and line boring, and explain when each is the right choice.

What Is Bore Welding?

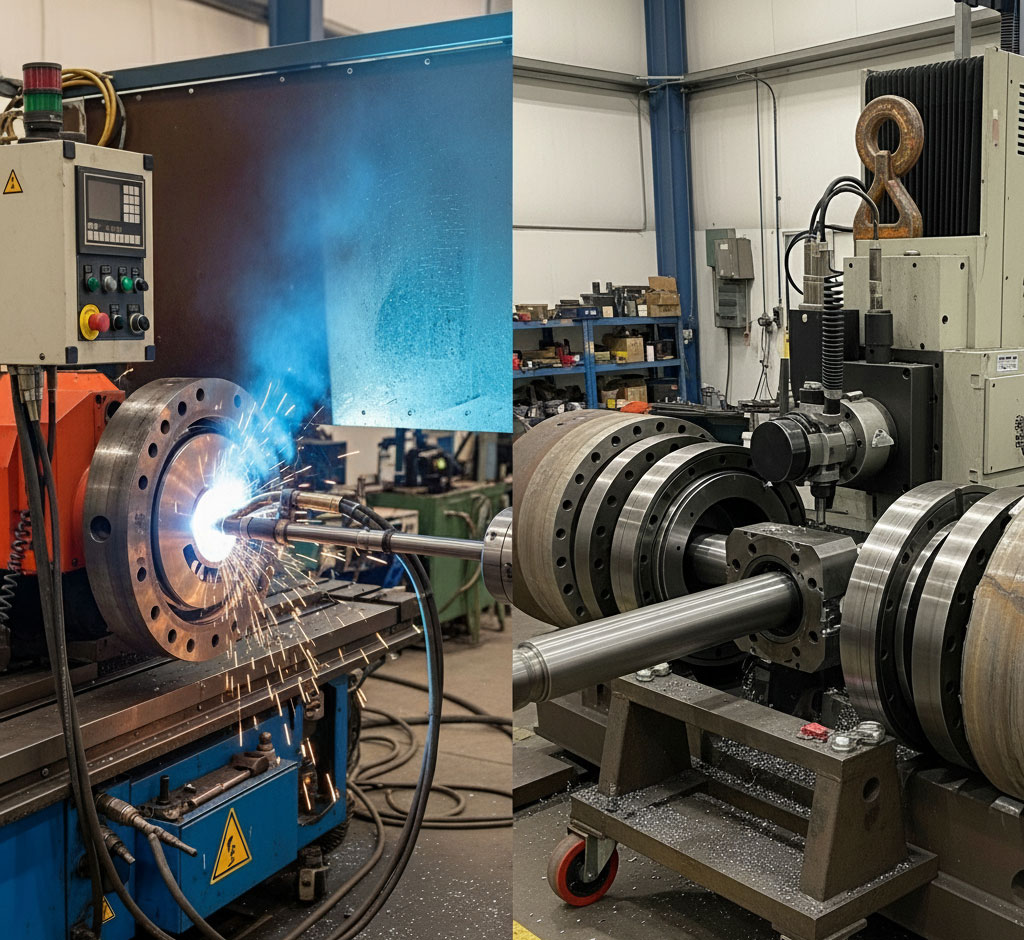

Bore welding is a process where worn or oversized bores are rebuilt using welding before being machined again. A welding attachment deposits filler metal around the damaged bore, restoring material that was lost due to wear. Once welded, the bore is then machined back to the correct size—often using a portable line boring machine for finishing.

- Advantages: Extends life of heavily worn parts, adds material for re-machining, suitable for very large bores.

- Limitations: Requires more time and heat input, not always needed if bore wear is minor.

What Is Line Boring?

Line boring is a precision machining process that restores a bore to its correct diameter and alignment. Using a boring bar, technicians remove damaged material until the bore is perfectly round again. It is commonly used for heavy equipment repairs such as excavator booms, loader arms, and bulldozer blades.

- Advantages: Fast, precise, no added material needed, restores alignment.

- Limitations: Cannot fix bores that are severely oversized without welding buildup.

Bore Welding vs Line Boring: Key Differences

| Aspect | Bore Welding | Line Boring |

|---|---|---|

| Purpose | Rebuilds worn bores by adding material | Machines bores back to round and aligned |

| Best For | Severely oversized or damaged bores | Moderately worn bores needing precision machining |

| Process | Welding followed by machining | Machining only |

| Time & Cost | Longer process, higher cost | Faster, lower cost if wear is minimal |

| Equipment | Bore welding unit + line boring machine | Portable line boring machine |

When to Use Bore Welding vs Line Boring

If the bore is only slightly worn, line boring alone is sufficient to restore it. However, if the bore is severely worn or oversized, bore welding is required first to build up material before line boring can bring it back to tolerance. In practice, the two methods are often combined.

- Use Line Boring: For moderate wear, misaligned bores, construction equipment, mining truck repairs.

- Use Bore Welding + Line Boring: For large excavator booms, marine rudders, or oversized bores that cannot be fixed by machining alone.

Conclusion

Bore welding and line boring are complementary repair methods, not competitors. Bore welding rebuilds worn areas, while line boring restores precision. For businesses maintaining heavy equipment, knowing when to apply each method ensures reliable repairs, reduced downtime, and cost savings.

Leave a Reply