Portable line boring machines allow technicians to restore worn bores directly on-site, saving time and avoiding the need to transport heavy equipment. Correct setup is essential to ensure accuracy, efficiency, and safety. In this guide, we walk through the step-by-step process of setting up a portable line boring machine.

Step 1 – Inspect the Work Area

Before setting up, clean the area around the worn bore. Remove dirt, grease, and debris that could affect machine mounting. Check for cracks or damage that may require welding before boring begins.

Step 2 – Mount the Bearing Supports

Bearing supports hold the boring bar in place. Secure them firmly to the workpiece using brackets or welding. Proper alignment of these supports is critical for accuracy. Use a spirit level or laser alignment tool to ensure they are straight.

Step 3 – Install the Boring Bar

Slide the boring bar through the mounted bearings. Make sure the bar is clean and free from damage. The bar should rotate smoothly within the bearings. Apply lubrication to reduce friction and extend tool life.

Step 4 – Align the Machine

Alignment ensures the new bore will be perfectly straight. Check the boring bar’s position through multiple bores if applicable. Adjust the bearings or brackets until the bar runs true. Misalignment will result in uneven cutting and poor fit.

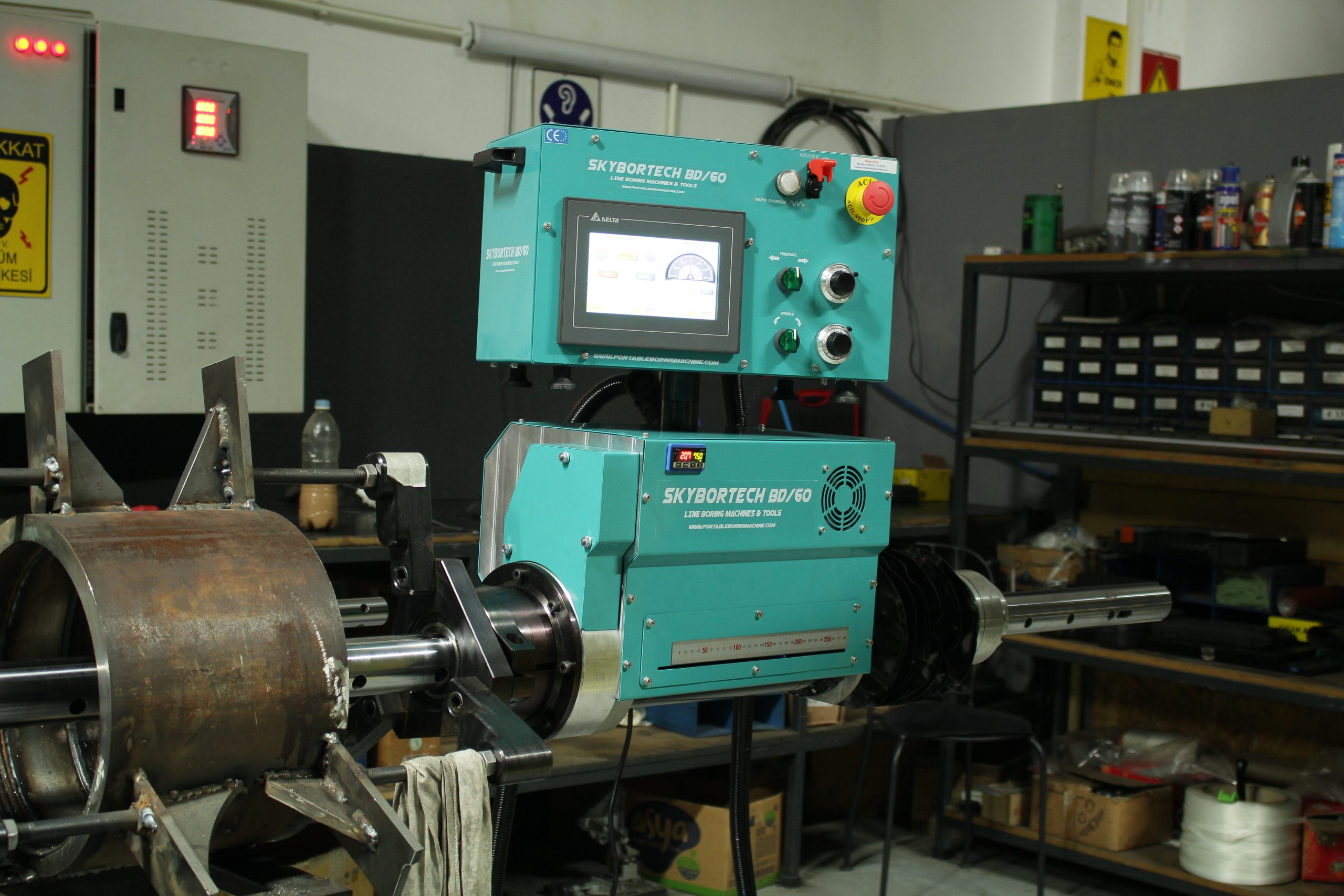

Step 5 – Attach the Drive Unit

Connect the drive motor (electric, hydraulic, or pneumatic) to the boring bar. Ensure all connections are tight and secure. Verify that the motor rotates the bar smoothly without excessive vibration.

Step 6 – Install the Tool Bit and Feed Mechanism

Mount the cutting tool into the tool holder on the boring bar. Adjust the tool position according to the required bore size. Attach the feed mechanism to control the cutting depth and movement of the tool across the bore.

Step 7 – Test Run and Final Adjustments

Before starting the actual machining, perform a slow test run. Check for vibrations, unusual noises, or tool misalignment. Make final adjustments to the feed rate, tool position, and motor speed.

Step 8 – Begin the Boring Operation

Once everything is aligned and secure, begin the boring operation. Monitor the process carefully, applying lubrication as needed. Maintain consistent feed and cutting speed to achieve a precise finish.

Safety Tips During Setup

- Always wear proper PPE (gloves, goggles, hearing protection).

- Secure all mounts and brackets before starting the machine.

- Never attempt adjustments while the machine is running.

- Keep hands and clothing away from rotating parts.

Conclusion

Setting up a portable line boring machine correctly is the foundation for a successful repair. With careful alignment, secure mounting, and proper safety measures, technicians can achieve precise, reliable results every time. Whether working on construction equipment, mining trucks, or marine shafts, accurate setup ensures maximum efficiency and long-lasting repairs.

Leave a Reply