Line boring is one of the most essential machining processes in industries where heavy equipment is used. It restores worn or misaligned bores to their original specifications, ensuring machinery continues to operate safely and efficiently. Portable line boring machines make it possible to perform these repairs directly on-site, saving time and cost. In this article, we explore the top 10 applications of line boring in heavy equipment repair.

1. Excavator Boom and Stick Joints

Excavators endure constant stress on their boom and stick joints. Over time, these pin holes become elongated and loose. Line boring restores the bores, ensuring proper pin fit and smooth operation of the arm.

2. Loader Arm Pivot Points

Wheel loaders and skid-steer loaders rely heavily on their arm pivot points for lifting. When these joints wear out, the machine loses precision and lifting efficiency. Portable line boring machines repair these points quickly without dismantling the loader.

3. Bulldozer Blade Mounts

Bulldozers operate under extreme conditions, and the blade mounts often wear down. Line boring restores the pin holes that connect the blade to the chassis, ensuring reliable pushing performance.

4. Crane Booms and Turntables

Cranes depend on precise alignment for safe lifting. Wear in boom joints or turntable assemblies can cause dangerous instability. Line boring ensures these bores remain within tight tolerances.

5. Mining Truck Chassis Connections

Mining haul trucks carry massive loads, which puts stress on their chassis connections. Line boring restores these bores, extending the life of the truck and reducing costly downtime.

6. Agricultural Machinery Linkages

Tractors, harvesters, and plows rely on multiple linkage points. When these holes wear, alignment problems occur. Line boring is a cost-effective way to bring them back to factory specifications.

7. Marine Rudders and Stern Tubes

In the marine industry, rudder shafts and stern tubes must be perfectly aligned. Any misalignment can compromise steering and propulsion. Line boring restores these bores to precise condition, even while the vessel is in dry dock.

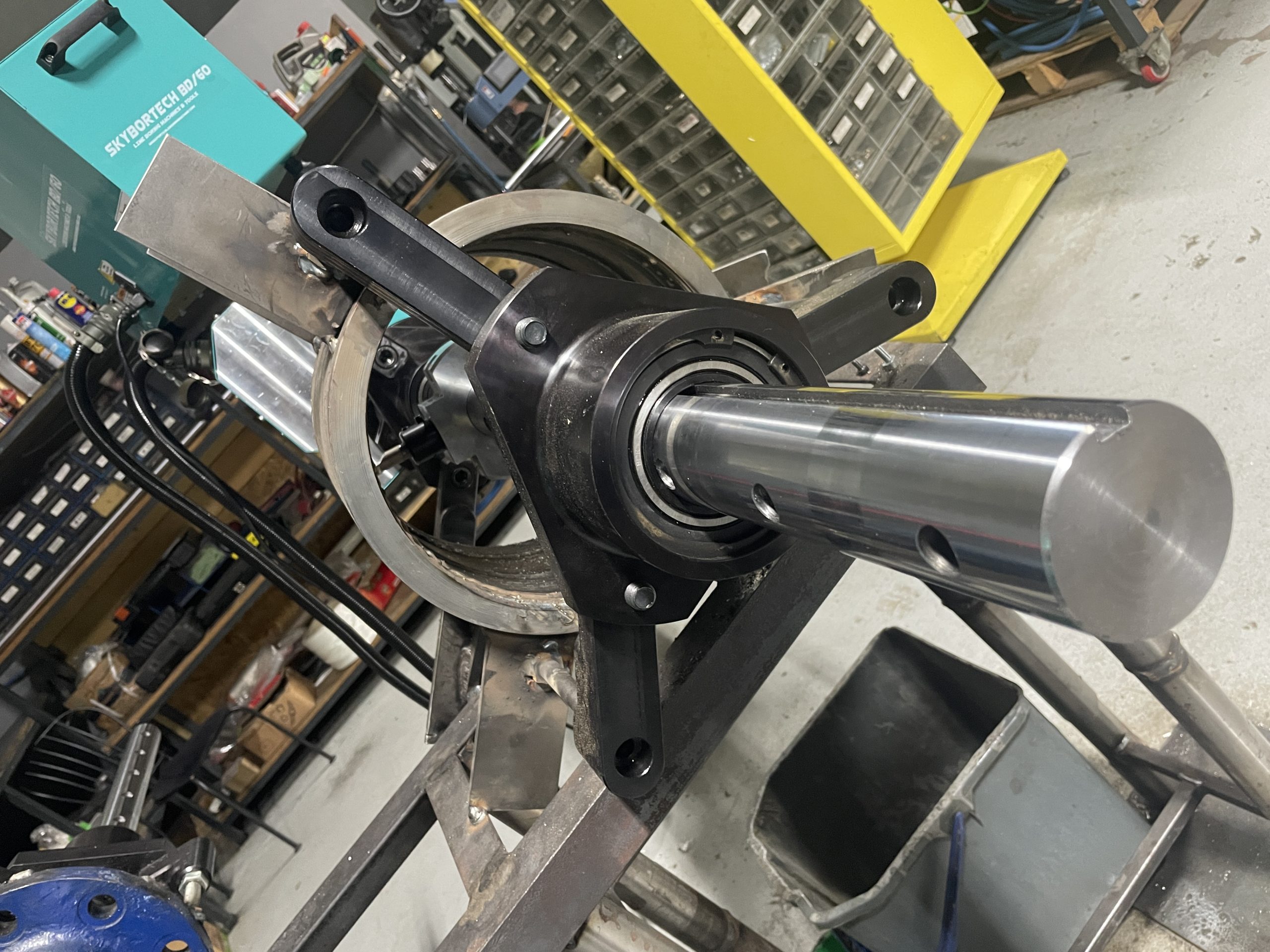

8. Hydraulic Cylinder Mounts

Hydraulic systems are critical in heavy machinery. When cylinder mounts wear out, hydraulic performance declines. Line boring repairs the mounts so cylinders fit tightly and function correctly.

9. Industrial Presses and Large Machinery

Factories use presses and heavy machines that require accurate alignment of shafts and pins. Line boring ensures these machines stay operational without needing full dismantling.

10. Custom Fabrication and Repair Projects

Beyond heavy equipment, line boring is also used in custom fabrication shops. Any situation where precision bores are needed—such as large gates, frames, or rotating structures—can benefit from portable line boring technology.

Conclusion

From construction and mining to marine and agriculture, line boring has countless applications in keeping heavy equipment running at peak performance. By using portable line boring machines, technicians can complete these critical repairs directly on-site, saving both time and money. If you rely on heavy machinery, line boring is not just a repair option—it’s an investment in long-term reliability.

Leave a Reply