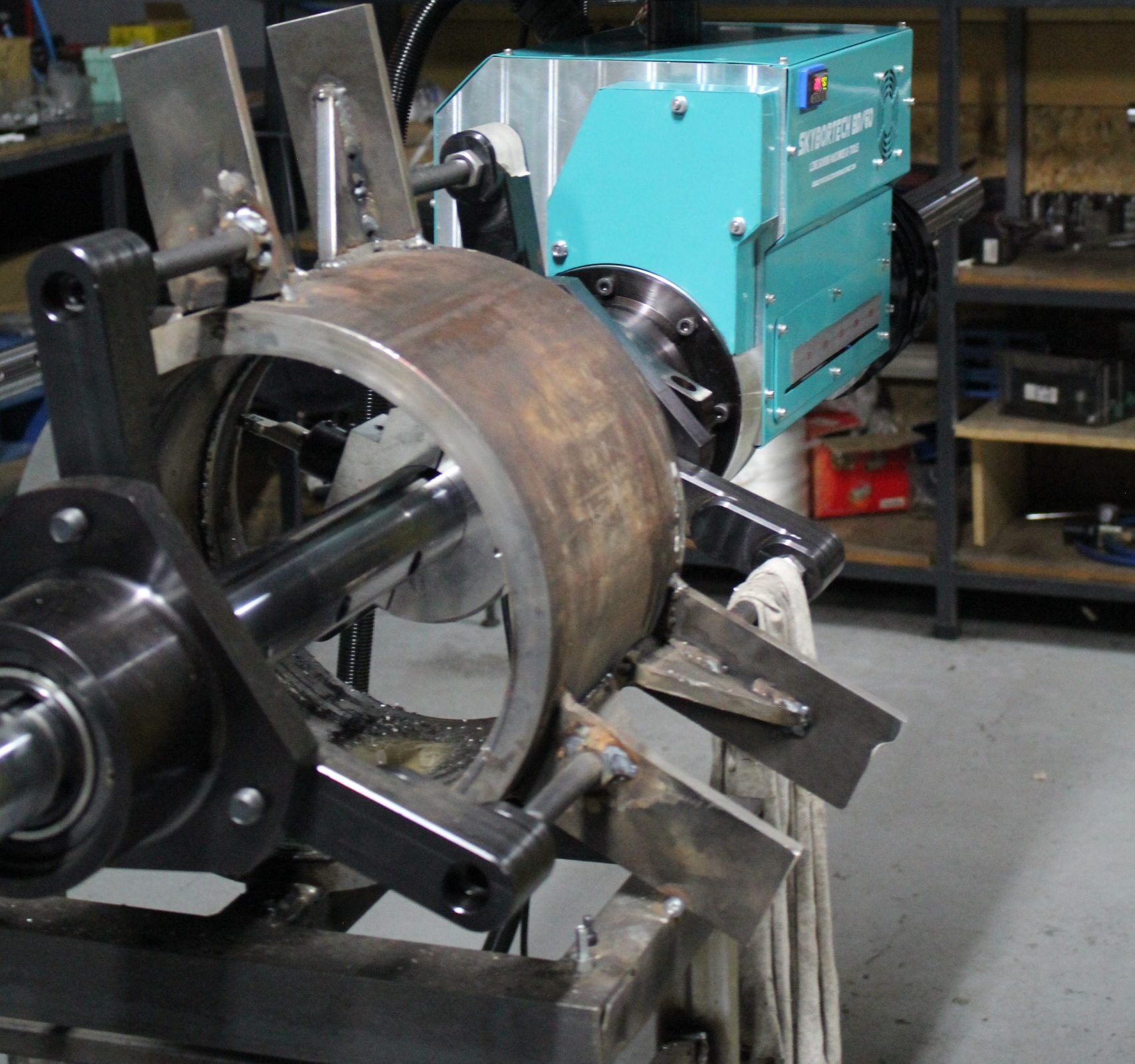

Tag: Field Machining Services

-

Line Boring vs Sleeving: What’s the Difference?

When bores in heavy equipment or industrial machinery become worn, two of the most common repair methods are line boring and sleeving. Both restore functionality, but they involve different processes, costs, and results. Understanding the differences helps technicians and equipment owners choose the right solution for each situation. What Is Line Boring? Line boring is…