Tag: Bore Welding

-

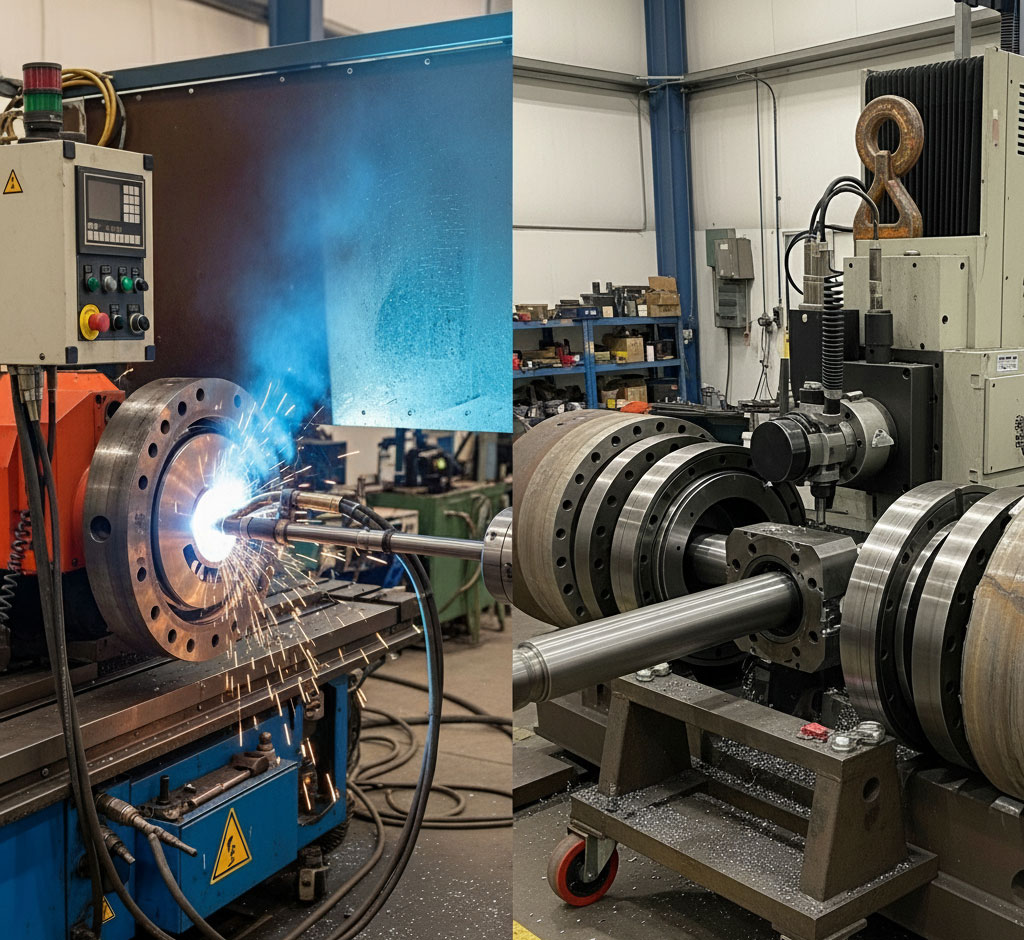

Bore Welding vs Line Boring: When Do You Need Each?

When bores in heavy equipment become worn or out of round, two repair methods are commonly used: bore welding and line boring. While they are often mentioned together, they are not the same process. Knowing the difference can save your business time and money. In this article, we compare bore welding and line boring, and…

-

Case Study: Repairing Excavator Boom Hinges with Portable Line Boring

Excavators are among the most widely used machines in construction and mining. Over time, their boom hinges and pin joints experience extreme stress, causing wear and misalignment. In this case study, we examine how portable line boring was used to repair worn boom hinges on an excavator, restoring precision and extending the machine’s service life.…

-

Line Boring vs Sleeving: What’s the Difference?

When bores in heavy equipment or industrial machinery become worn, two of the most common repair methods are line boring and sleeving. Both restore functionality, but they involve different processes, costs, and results. Understanding the differences helps technicians and equipment owners choose the right solution for each situation. What Is Line Boring? Line boring is…